The Ideal Methods for Maintaining and Repairing Bridge Expansion Joints

On a sunny day in an urban city that has lots of traffic and bridges connecting regions, as you walk across a bridge, you see some workers gathered nearby. They’re talking about something important called bridge expansion joints, which are like flexible parts of the bridge. These components help the bridge remain strong when it gets bigger or smaller because of heat or cold, just like our joints do when we stretch or bend. The workers check out clean, and repair these parts to make the bridge safe for all who use it, especially motor vehicles, bikes, and people. In this article, we’ll discuss how they maintain these bridge parts to keep the bridge safe for everyone.

About Expansion Joints for Bridges

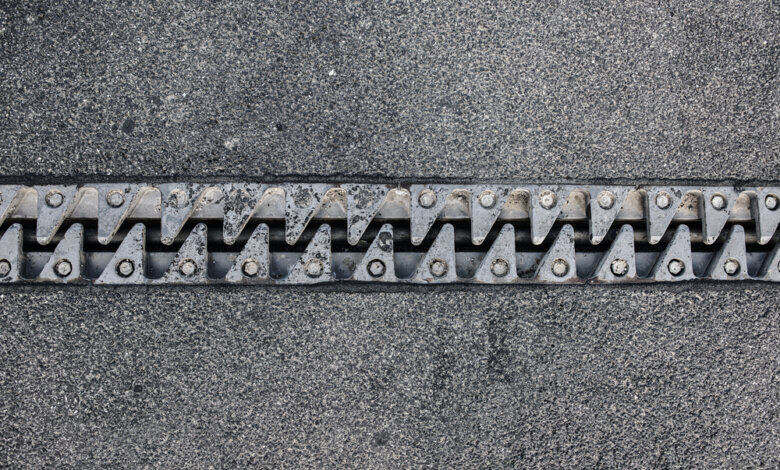

Expansion joints are like the flexible joints in our bodies that allow movement without causing damage. In the context of bridges, these joints adjust the expansion and contraction due to temperature variations and other environmental elements. Bridges could develop cracks and structural issues over time without proper expansion joints.

What is the Importance of Expansion Joints?

It’s important to consider the importance of expansion joints in bridge construction. These joints are essential parts that adjust to the shifting climatic conditions and dynamic pressures that bridges must withstand. Expansion joints shield the bridge structure from vibrations, thermal expansion, and contraction by functioning as shock absorbers. In addition to ensuring the bridge’s safety, this lengthens its durability.

These enable the bridge to breathe, accommodating movements occurring naturally due to temperature fluctuations and traffic loads. Without these flexible joints, the bridge would be susceptible to stress, leading to potential cracks, structural damage, and compromised safety. Recognizing their importance is essential for their safety and the well-being of the communities relying on these vital structures for connectivity and transportation.

What Are the Maintenance Tips for Expansion Joints?

1. Routine Inspections

Regular inspections are the foremost step in ensuring the health of expansion joints for bridges. Regular visual checks can assist in identifying any signs of wear, debris buildup, or damage. Inspection frequency may vary based on location, climate, and traffic volume.

2. Cleaning

Keep these joints free from debris such as leaves, dirt, and other particles. Accumulated debris can restrict the movement of the joints, leading to possible damage. Regular cleaning guarantees that the joints can function perfectly.

3. Lubrication

Applying appropriate lubricants to the expansion joints helps lower friction and enables smoother movement. This is particularly significant in regions with extreme temperatures, as lubrication prevents the joints from seizing due to thermal expansion.

4. Sealant Checking and Replacement

The sealant in these connections serves as a protective barrier, keeping water and debris out. Inspect the sealant regularly and replace it if it deteriorates, cracks, or has gaps. Proper sealing is crucial for preventing corrosion and extending the life of the joints.

5. Monitoring Structural Integrity

Regularly monitor the structural integrity of the expansion joints to ensure they are functioning as designed. Look for signs of rust, corrosion, or structural damage, and address any issues promptly to maintain the overall stability and safety of the bridge.

What Are Common Problems With Bridge Expansion Joints?

- Expansion joint wear: Continuous traffic and weather conditions can cause the expansion joints to wear out over time.

- Water infiltration: Rain and moisture can seep into the joints, leading to corrosion and weakening of the bridge structure.

- Debris accumulation: Debris like leaves, dirt, and sand can collect in the joints, hindering their movement and causing potential damage.

- Joint misalignment: Due to heavy traffic loads or improper installation, expansion joints may become misaligned, affecting their functionality.

- Sealant deterioration: The sealant used in joints can deteriorate over time, losing its ability to prevent water ingress and contributing to joint failure.

Repairing Expansion Joints

Proactive Problem Detection

Preventing major damage requires quick identification of potential problems. As was already said, regular inspections are essential for spotting issues early on and facilitating simpler, less expensive repairs. Through proactive inspections, you can avoid serious damage and costly repairs, ensuring that your systems run smoothly and efficiently.

Replacing Damaged Parts

If certain components of the expansion joint are damaged beyond repair, consider replacing them promptly. This may include replacing damaged seals, bearings, or other vital parts. Immediate replacement ensures the continued functionality of the expansion joint.

Resealing Joints

Over time, the sealant in these joints may wear out or crack, compromising effectiveness. Resealing the joints with a high-quality sealant helps maintain the joint’s integrity and prevents water and debris infiltration. This simple maintenance task can extend the lifespan of your joints and ensure they continue to function optimally, reducing the risk of leaks and damage.

Preventing Proactive Corrosion

Metal components of expansion joints are at risk for corrosion. Applying anti-corrosive coatings or using corrosion-resistant materials during repairs can significantly increase the life of the joints. By dealing with corrosion proactively, you can improve the life of your expansion joints and avoid costly replacements or repairs in the future.

Implementing Regular Maintenance Schedules

Establishing a consistent maintenance schedule ensures that the expansion joints are regularly inspected, cleaned, and serviced as needed. This proactive approach can significantly prolong the lifespan of the joints and minimize the risk of unexpected failures.

Your Trusted Source for High-Quality Expansion Joints

Polycrafts Pvt Limited stands out as a leading manufacturer of road safety equipment in Pakistan, renowned for its superiority in producing high-quality rubber expansion joints under the brand name Flexo Guard. Utilizing advanced technologies, they ensure their products meet the highest standards, offering clients reliable solutions for their bridge infrastructure needs. The company is dedicated to modern manufacturing practices, guaranteeing high-end quality that meets strict industry standards.

Whether you are searching for bridge, railway, pipe expansion joints, or masonry expansion joints, Polycrafts is committed to delivering durable and dependable solutions.

In the End

Expansion joints are necessary for the health and longevity of bridges. Regular maintenance, including inspections, cleaning, and lubrication, ensures these joints function optimally. When repairs are needed, early identification of issues and proactive measures such as element replacement and resealing can prevent more extensive damage.

By prioritizing the maintenance and repair of expansion joints, we contribute to our bridges’ overall safety and durability. As we travel across these important structures, it’s crucial to appreciate the behind-the-scenes efforts that go into keeping them safe and reliable for years to come.

Ready to ensure the longevity of your bridges? Contact Polycrafts Pvt Limited. Explore their top-quality Flexo Guard expansion joints for bridges, manufactured using cutting-edge technology. Secure your infrastructure’s future – reach out today for customized solutions at affordable prices. Let’s build bridges that will resist the test of time.

Make sure to explore the rest of the site for more fascinating Blogs!